Introduction

As sustainable manufacturing and plastic recycling gain importance, PP Battery Grinding has become a key process in the industry. Specifically, polypropylene (PP), a strong, durable, and recyclable plastic, makes up the outer casings of used lead-acid batteries.

Recycling PP battery scrap not only helps reduce battery waste but also cuts production costs and supports a circular economy in plastics by transforming discarded battery casings into valuable raw materials.

This blog covers everything you need to know about PP Battery Grinding, including its process, key features, and applications, as well as how recyclers and manufacturers can benefit from using recycled PP material and recycled plastic pellets for sale.

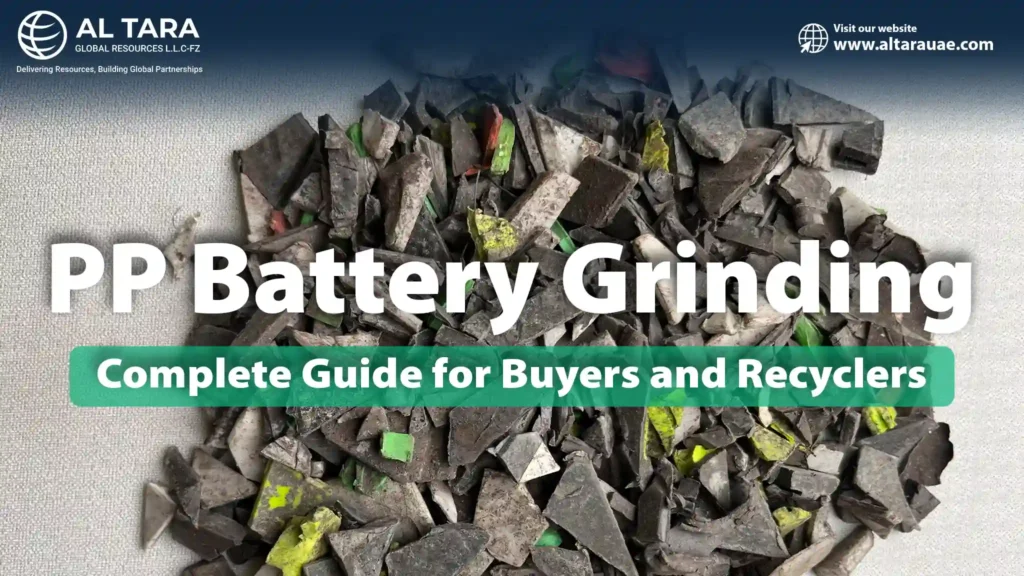

What is PP Battery Grinding?

Recyclers first collect PP Battery Grinding Scrap from the outer shells of old car or industrial batteries. Then they dismantle the batteries and clean the plastic parts. After that, they grind the PP casings into small flakes or regrind using plastic grinding machines or granulators. Next, they melt and process these materials into PP granules or pellets. As a result, the recycled PP becomes a low-cost alternative to virgin polypropylene. It also supports PP recycling, helps manufacturers, and promotes sustainability and efficient use of resources.

🚀 Buy & Sell PP Battery Scrap in UAE 🚀

Common forms of PP Battery Scrap include:

- PP Battery Grinding – finely ground PP flakes from battery casings.

- PP Battery Regrind – cleaned and sorted recycled PP ready for reprocessing.

- PP Battery Flakes – washed plastic flakes used for pelletizing.

Each form plays a vital role in the battery recycling process, turning waste into usable plastic raw material.

Key Features of PP Battery Grinding Scrap

- High Heat and Chemical Resistance – as a result, it is ideal for various industrial plastic recycling applications.

- Durable and Impact-Resistant – therefore, it retains its toughness even after multiple recycling cycles.

- Cost-Effective – Not only does it cost less than virgin PP resin, but it also helps manufacturers save money and promote sustainability.

- Eco-Friendly – consequently, it helps reduce landfill waste while actively promoting plastic recycling.

- Easily Available – therefore, it can be sourced in bulk from used battery casings worldwide.

Applications and Uses

Recycled PP Battery Regrind and PP Battery Flakes find wide use across various industries, including:

- Automotive Industry: Used to produce battery cases, dashboards, panels, and other components.

- Household Products: Buckets, storage containers, and utility items.

- Construction Sector: Pipes, fittings, and sheets.

- Packaging Industry: Durable containers and plastic pallets.

- Electrical and Industrial Uses: Switchgear housings and protective casings.

Many recyclers use plastic pulverizers and granulators to prepare PP regrind for reuse. At the same time, as industries focus more on sustainable production, recycled PP battery material is gradually replacing virgin plastic in manufacturing.

PP Battery Scrap Price and Market Overview

The price of PP Battery Scrap depends on material quality, color purity, and contamination. As a result, clean and well-sorted PP battery regrind sells for a higher price. In addition, its ready-to-use quality for reprocessing makes it even more valuable.

Similarly, like other recycled plastics, the prices of PP granules and PP dana fluctuate according to factors such as:

- Market demand in automotive and packaging sectors.

- Local recycling capacity and availability.

- Oil and virgin PP resin prices.

The prices of plastic grinding machines, granulators, and even used machines affect recycling costs. At the same time, as the global plastic recycling market grows rapidly, PP battery recycling offers a promising business opportunity for recyclers and manufacturers.

PP Battery Recycling Process

The recycling of PP Battery Scrap involves several key stages to ensure clean and high-quality output:

- Battery Collection and Dismantling: Workers safely open used batteries and separate the plastic, lead, and acid.

- Washing and Cleaning: The PP casings are carefully washed to remove acid, dust, and other contaminants.

- Grinding Process: Clean plastic parts are ground into flakes or regrind using specialized plastic recycling machines or plastic grinding machines.

- Pelletizing and Extrusion: The PP regrind is melted and turned into PP granules or PP dana for reuse.

- Quality Control and Packaging: After testing for MFI, density, and purity, the recycled PP is carefully packed for sale to ensure high quality at every step.

This process ensures consistent quality and promotes sustainable plastic recycling and battery recycling practices.

Why Choose Recycled PP from Battery Scrap?

Recycled PP battery material offers several advantages over virgin resin:

- Cost Savings – recycled PP is significantly cheaper than new plastic.

- Environmentally Responsible – consequently, it helps reduce carbon emissions while promoting efficient battery waste recycling.

- Strong and Reusable – as a result, it maintains its physical properties even after multiple recycling cycles.

- Business Opportunities – consequently, the growing market for PP and battery recycling offers promising prospects for recyclers and manufacturers

- Easy to Source – it is available from reliable recycling companies, where you can buy plastic recycling machines or recycled plastic pellets.

Using recycled PP saves money and also supports sustainability. In addition, it helps global efforts for resource efficiency and responsible manufacturing.

Choosing the Right Supplier

To ensure consistent quality and a reliable supply, buyers should work only with verified PP Battery Scrap suppliers. In addition, they should consider these key factors:

- Compare Market Rates: Check PP battery scrap and PP regrind prices from multiple suppliers.

- Quality Certifications: Ensure suppliers provide testing reports and quality certificates.

- Clean and Dry Material: Verify that the PP regrind is acid-free and contamination-free.

- Consistency: Choose suppliers with uniform color and particle size.

- Steady Supply: Partner with suppliers capable of meeting regular industrial demand.

Whether buying or selling PP Battery Grinding in the UAE, always partner with a verified local supplier. Furthermore, AL TARA Global Resources L.L.C‑FZ (Dubai) excels in trading plastic raw materials on an international scale.

Reliable suppliers ensure smooth operations and better production output for industrial plastic recycling businesses.

Market Outlook for Recycled PP in UAE

Thanks to its advanced recycling infrastructure, the UAE is becoming a major hub for polypropylene recycling and also enjoys strong export potential.

Key market trends include:

- Increased use of recycled PP in packaging, automotive, and construction sectors.

- Investment in modern PP grinding, plastic recycling machines, and plastic granulator machines.

- Government initiatives promoting waste management and battery waste recycling.

- Growing export opportunities for recycled plastic pellets for sale to Asia, Africa, and Europe.

Offering competitive pricing and consistent quality, the UAE’s PP recycling sector is poised for strong, sustainable growth.

Role in Sustainability

Recycling PP Battery Scrap helps the environment by:

- Supporting circular economy in plastics where waste becomes raw material.

- Reducing dependence on virgin plastic production.

- Minimizing plastic waste in landfills and oceans.

- Lowering carbon emissions from manufacturing.

By learning how to recycle batteries and using plastic recycling machines, industries make a big step toward a cleaner and more resource-efficient future.

Conclusion

Industries use PP Battery Grinding Scrap as a high-quality source of recycled polypropylene to save costs and support sustainability. In addition, because of its strong market demand, eco-friendly benefits, and many industrial uses, PP battery recycling is becoming a profitable and important part of the global plastic recycling industry.

By working with trusted PP battery scrap suppliers, businesses ensure quality and consistency while also gaining long-term value. In addition, this helps them stay competitive and protect the planet.

FAQs

1. What is PP Battery Scrap used for?

It’s used to make automotive parts, containers, and industrial products.

2. How is PP Battery Scrap recycled?

It’s cleaned, ground, and pelletized into PP granules or PP dana.

3. What is the PP Battery Scrap price in UAE?

It varies depending on quality, purity, and market demand.

4. Is PP recycling profitable in Dubai?

Yes, it’s a growing and profitable recycling business in the UAE.

5. Where can I buy PP Battery Regrind?

From verified plastic scrap and recycling suppliers across the UAE.

6. Where can I buy or sell PP Battery Grinding scrap in the UAE?

You can buy or sell PP Battery Grinding directly through AL TARA Global Resources LLC-FZ, a verified supplier based in Dubai.